Concept

The highly specialized solutions from Wet Wipe have been developed to reduce the time you spend on cleaning and disinfecting.

By introducing a single-use cleaning & disinfection concept you eliminate unnecessary washing, transport and product control, which makes the work flow easier, safer and more efficient.

The Wet Wipe cloths have been developed in cooperation with the Danish Occupational Health Services with special focus on ergonomics, user friendliness and the work environment.

The products are colour coded, thus helping the user to quickly identify the correct product. The products are designed in a way that eliminates the need for manual mixing and measuring of chemicals.

By using single-use wipes, contamination of the workstation as well as the route of infection is minimized.

Four concept pillars

The highly specialized solutions from Wet Wipe have been developed to reduce the time you spend on cleaning and disinfecting.

By introducing a single-use cleaning & disinfection concept you eliminate unnecessary washing, transport and product control, which makes the work flow easier, safer and more efficient.

The Wet Wipe cloths have been developed in cooperation with the Danish Occupational Health Services with special focus on ergonomics, user friendliness and the work environment.

The products are colour coded, thus helping the user to quickly identify the correct product. The products are designed in a way that eliminates the need for manual mixing and measuring of chemicals.

By using single-use wipes, contamination of the workstation as well as the route of infection is minimized.

Levels

Within surface disinfection we have products that are designed for the different types of levels from general cleaning, routine disinfection to isolation and outbreaks.

Thanks to the uniquely perforated surface of the cloth it enables you to remove 99,9% of bacteria while wiping surfaces.

..

1. Cleaning

2. Routine Disinfection

3. Isolation and outbreak

Lean philosophy

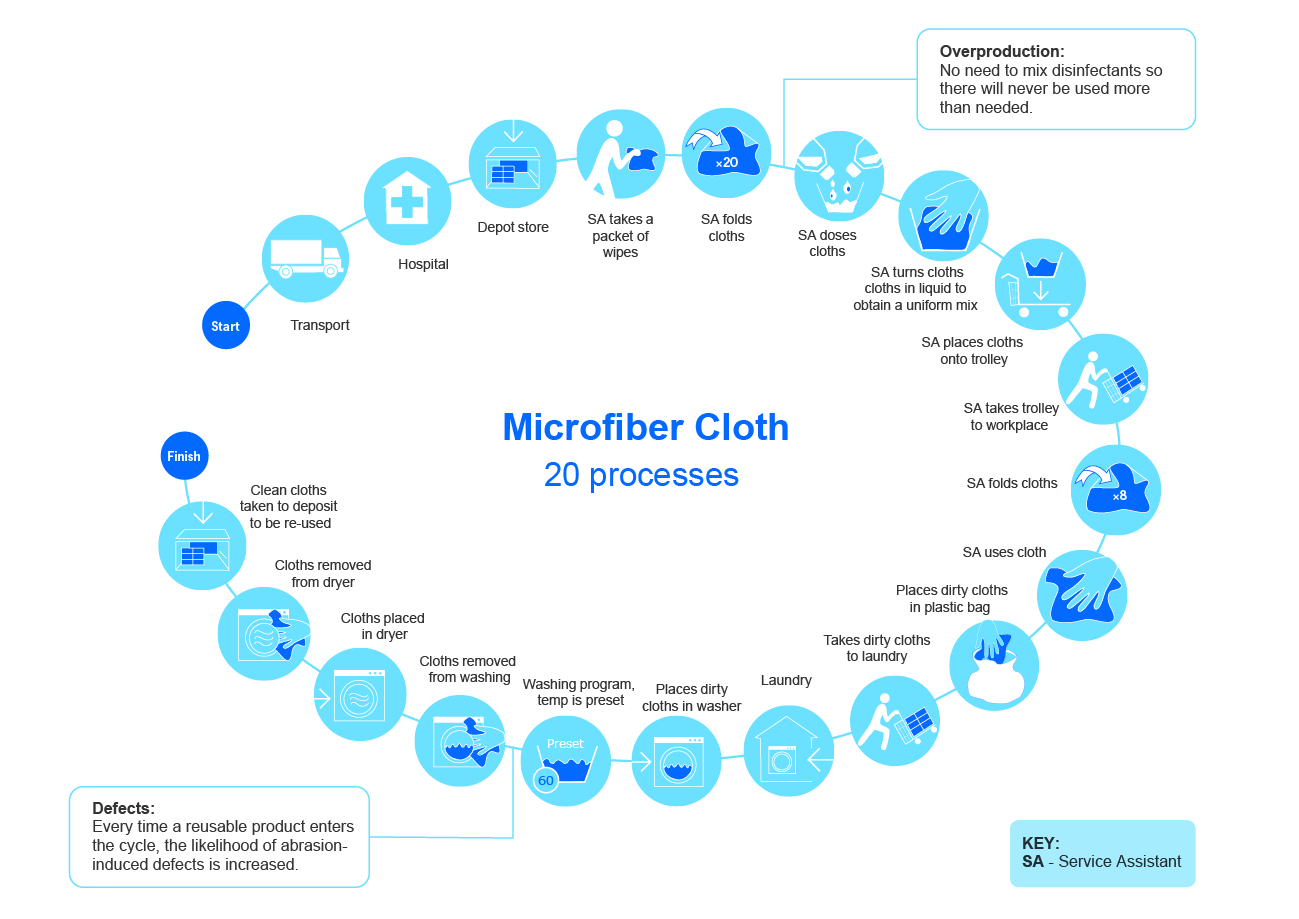

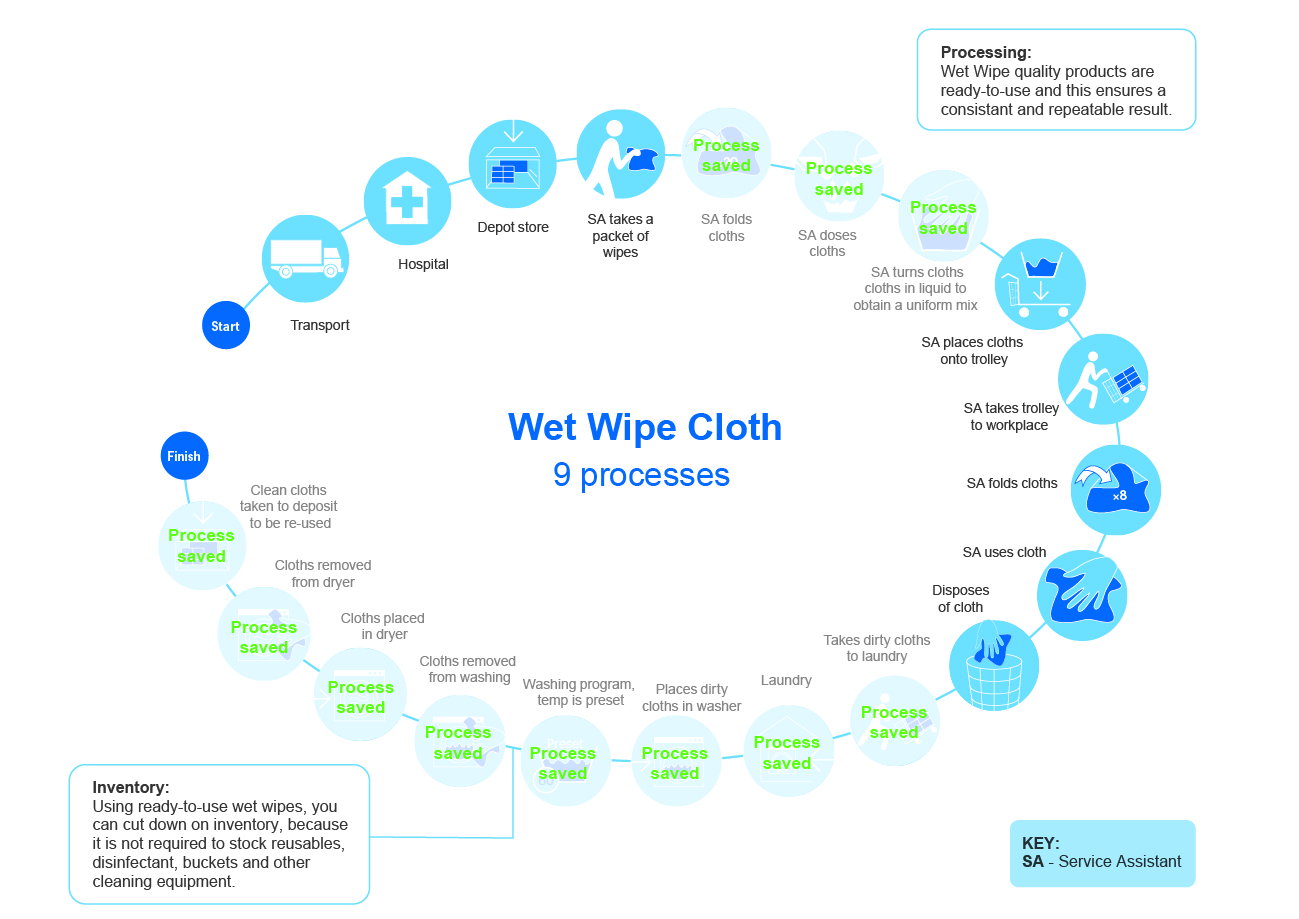

The core idea of Lean is to maximize users value while minimizing waste. Lean means simply creating more value for users with fewer resources.

Eliminating waste along the entire value stream, instead of at isolated points, creates processes that need less human effort, less space, less capital, and less time. This makes products and supply services at far lower costs and with fewer defects, compared to traditional business systems. As an alternative to reusables we offer improvements to all principle process areas.

Wet Wipes ensure consistent results in contrast to reusables, where quality declines over time and human error increases the likelihood of non-uniform blending. Wet Wipes save time, money and above all, human error. Using a Lean working process contributes in a direct and measurable way to better hygiene.

Eliminating waste along the entire value stream, instead of at isolated points, creates processes that need less human effort, less space, less capital, and less time. This makes products and supply services at far lower costs and with fewer defects, compared to traditional business systems. As an alternative to reusables we offer improvements to all principle process areas.

Wet Wipes ensure consistent results in contrast to reusables, where quality declines over time and human error increases the likelihood of non-uniform blending. Wet Wipes save time, money and above all, human error. Using a Lean working process contributes in a direct and measurable way to better hygiene.